A vacuum chamber is an essential piece of equipment widely used in various industries to achieve controlled, low-pressure environments. It is primarily designed to extract air and other gases from within the chamber, facilitating rapid degassing and material processing.

1. Functionality of a Vacuum Chamber

A vacuum chamber operates by creating a sealed, low-pressure environment. This is accomplished by using a vacuum pump to remove air and gases from the chamber. The resulting vacuum environment helps to:

Speed up the degassing process: When raw materials, such as resins, oils, or adhesives, are exposed to vacuum, the chamber quickly removes any entrapped air bubbles.

Enhance mixing and blending efficiency: When materials are mixed under vacuum conditions, the absence of air allows for more efficient and thorough blending. This is particularly important in applications that require the uniform distribution of additives, pigments, or other components, such as in pharmaceuticals, chemicals, and food processing.

2. Design and Construction

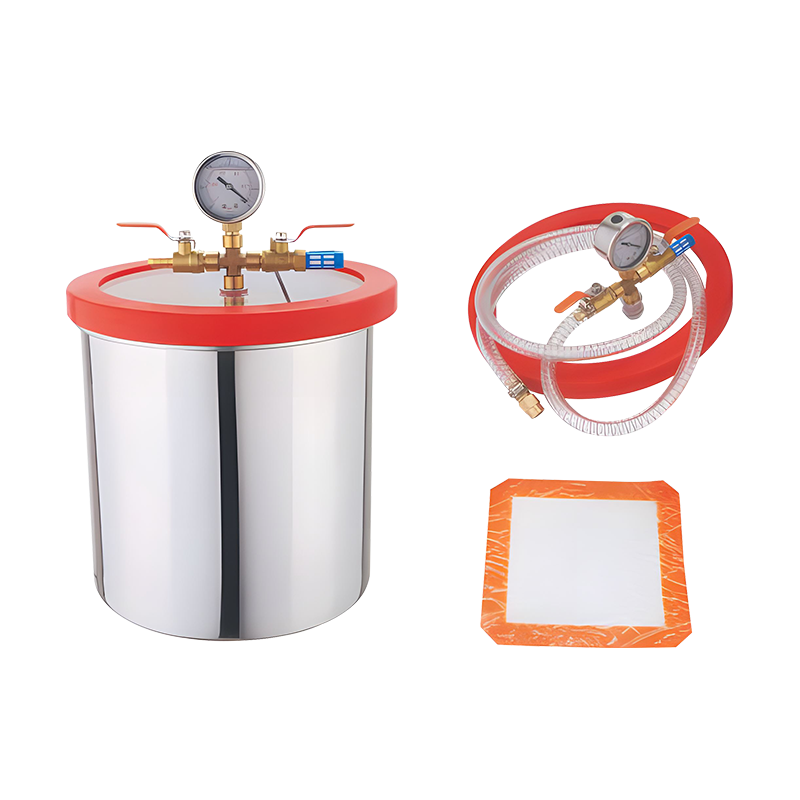

Vacuum chambers come in various designs, depending on the specific application and the level of vacuum required. The main components typically include:

Chamber Material: The chamber is typically made from durable materials like stainless steel or aluminum to withstand the pressure differences and prevent contamination.

Vacuum Pump: A vacuum pump is responsible for creating the low-pressure environment within the chamber. The pump removes air and gases to a pre-defined level, typically measured in millibar or torr.

Seals and Gaskets: The integrity of the vacuum chamber depends on tight seals and gaskets that ensure no leakage of air or gases. High-quality seals are essential for maintaining the vacuum conditions during operation.

Vacuum Gauges: Accurate vacuum gauges are used to monitor the pressure inside the chamber and ensure that it remains within the desired range for specific applications.

Control Systems: Modern vacuum chambers often feature automated control systems that allow users to set and monitor parameters such as vacuum levels, temperature, and processing time. These systems help improve the repeatability and precision of operations.

3. Applications of a Vacuum Chamber

The versatility of vacuum chambers makes them applicable in numerous industries, including:

Material Processing: In industries such as aerospace, automotive, and electronics, vacuum chambers are used to degas materials like resin and composites, ensuring that no air bubbles are trapped within the material, which could weaken the final product.

Food Industry: Vacuum chambers are employed in food processing applications like vacuum sealing, where the removal of air extends shelf life and prevents oxidation. They are also used in food dehydration processes, where low pressure helps to remove moisture without affecting the nutritional value.

Pharmaceuticals and Biotechnology: In these fields, vacuum chambers are used to handle sensitive substances that could degrade in the presence of air or moisture. This includes the processing of pharmaceuticals, where contamination must be avoided, and the production of certain biologics.

Electronics and Semiconductors: Vacuum chambers are crucial for manufacturing high-precision components such as semiconductors, where the vacuum environment ensures that impurities do not interfere with the production process.

Vacuum Coating: In industries like optics, electronics, and automotive, vacuum chambers are used in thin film deposition processes such as sputtering and evaporation to coat products with materials like metals, oxides, or polymers in a controlled, low-pressure environment.