Aug 22, 2025

The primary function of a Stainless Steel Vacuum Chamber is to allow processes to occur in a low-pressure or high-vacuum environment. These chambers are commonly used in semiconductor manufacturing, aerospace testing, pharmaceutical research, and thin-film deposition. The structural integrity and material properties of the chamber ensure that the internal vacuum is maintained over time, even under rigorous operating conditions.

One of the important aspects to consider is the size of the Stainless Steel Vacuum Chamber. These chambers can vary significantly in dimensions depending on the intended application. For laboratory-scale setups, a small chamber might measure 300 mm in diameter and 400 mm in height. In contrast, industrial-scale versions can exceed 1500 mm in diameter and stand over 2000 mm tall. The size of the Stainless Steel Vacuum Chamber must be chosen based on volume requirements and available installation space.

The wall thickness of a Stainless Steel Vacuum Chamber is directly related to the pressure differential it must withstand. A typical chamber designed for high vacuum conditions may have wall thicknesses ranging from 6 mm to 25 mm. This ensures that the chamber does not deform under vacuum stress. The structural strength provided by thicker walls is also critical when the chamber undergoes repeated vacuum cycles.

Material selection is another important specification. A Stainless Steel Vacuum Chamber is commonly made from grades such as 304 or 316 stainless steel. These grades offer corrosion resistance, mechanical durability, and compatibility with vacuum processes. 316 stainless steel, in particular, is preferred when the chamber is exposed to harsh chemicals or elevated temperatures, as it provides improved resistance to pitting and stress corrosion.

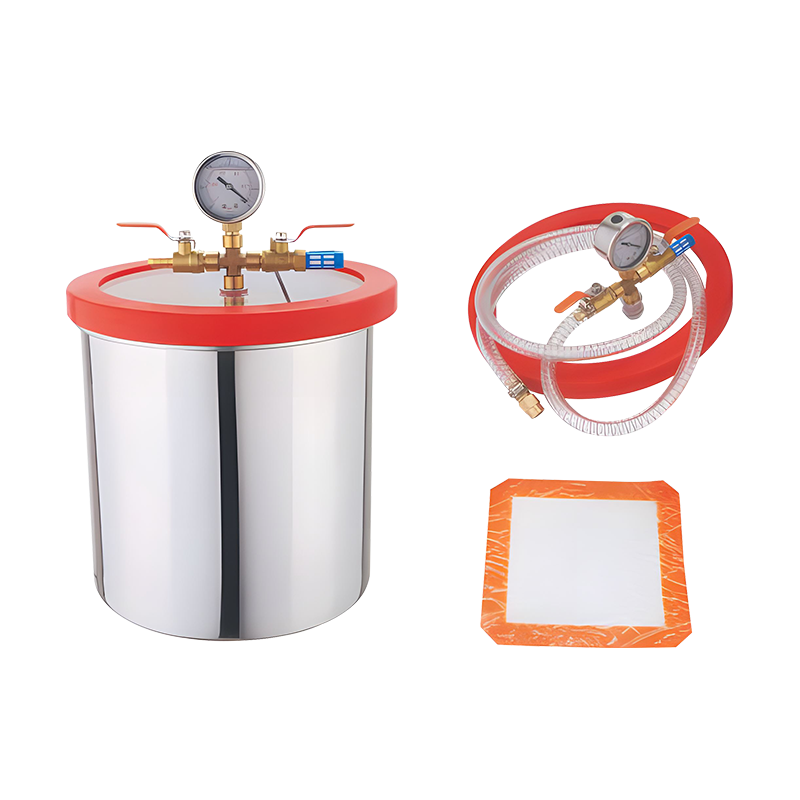

In addition to physical dimensions, the sealing method used in a Stainless Steel Vacuum Chamber must be considered. Flanges and seals are designed to maintain a vacuum-tight environment. Conflat (CF) flanges, ISO flanges, and KF fittings are commonly used standards, each with its own advantages depending on the pressure range and system requirements. The precision of the flange surfaces and the quality of the sealing material directly affect the vacuum performance of the chamber.

Another key specification is the achievable vacuum level. A well-designed Stainless Steel Vacuum Chamber can reach high or ultra-high vacuum ranges, depending on the pump system used. High vacuum chambers often reach pressures as low as 10⁻⁶ mbar, while ultra-high vacuum chambers can achieve levels of 10⁻⁹ mbar or lower. The surface finish and internal cleanliness of the chamber are important factors that contribute to achieving and maintaining these vacuum levels.

Chamber ports and access points are also integral to the overall specification. A Stainless Steel Vacuum Chamber often includes multiple ports for electrical feedthroughs, gas inlets, viewports, and sensor connections. These ports must be precisely machined and located based on the experimental or process requirements. Each port adds functional versatility to the chamber and must be designed to prevent leaks under vacuum conditions.

Temperature tolerance is another important parameter. Many processes inside a Stainless Steel Vacuum Chamber require heating or cooling. The chamber must be able to withstand internal temperatures from sub-zero levels up to 400°C or more, depending on the application. The stainless steel structure, combined with appropriate insulation and thermal control systems, helps manage these temperature variations.

Weight is a practical consideration, especially for large chambers. A typical medium-sized Stainless Steel Vacuum Chamber may weigh between 150 to 500 kilograms. This requires appropriate support structures and installation planning. Mounting systems, transport considerations, and integration into existing infrastructure all need to take the chamber's dimensions and weight into account.