Nov 21, 2025

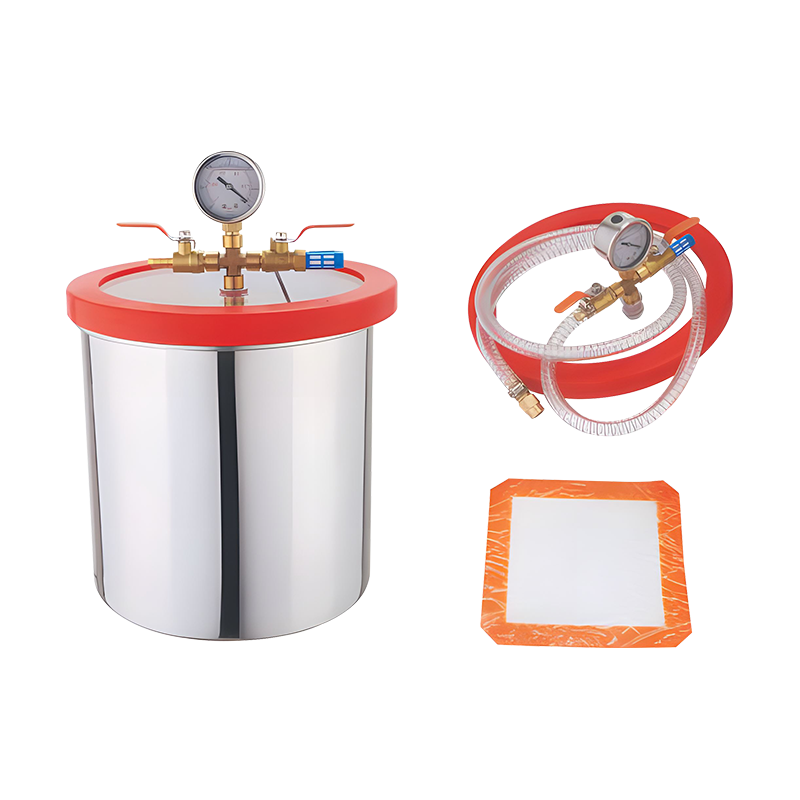

Stainless steel vacuum chambers are specialized enclosures designed to maintain a low-pressure environment for scientific, industrial, and manufacturing applications. These chambers allow experiments, processes, or tests to occur in a controlled environment with reduced air or gas presence. The choice to use a stainless steel vacuum chamber depends on the specific requirements of the process, material compatibility, and operational conditions.

1. Material and Chemical Compatibility

One of the primary reasons to use a stainless steel vacuum chamber is the need for compatibility with the materials or substances involved in the process.

Resistance to corrosion and contamination: Stainless steel offers high resistance to corrosion from chemical vapors, acids, or solvents commonly used in laboratory and industrial processes. For example, in thin-film deposition for electronics, reactive gases may interact with metal surfaces. A stainless steel chamber minimizes contamination and maintains a clean environment.

Non-reactivity with process materials: Certain chemical or metallic substances can react with other materials such as aluminum or carbon steel. Using stainless steel ensures that the chamber walls do not interfere with experiments or degrade over time. For instance, when performing vacuum drying of chemical compounds, stainless steel prevents unintended reactions with the container.

Ease of cleaning and maintenance: Stainless steel surfaces are smooth and durable, allowing for thorough cleaning between processes. This is important in applications where cross-contamination could affect the quality of results, such as in pharmaceutical production or material testing.

Ensuring chemical and material compatibility is a fundamental consideration for maintaining process integrity and chamber longevity.

2. Pressure and Process Requirements

Another key factor in deciding when to use a stainless steel vacuum chamber is the pressure level and specific process requirements.

High vacuum capability: Stainless steel chambers can maintain very low pressures, suitable for processes like vacuum coating, degassing, or electron microscopy. A chamber that maintains a stable vacuum allows precise control of the environment for sensitive experiments.

Temperature tolerance: Many vacuum processes involve heating or cooling components inside the chamber. Stainless steel’s ability to withstand high and low temperatures without deformation makes it suitable for applications such as curing resins, annealing metals, or drying components under vacuum.

Uniformity and control: Processes requiring uniform pressure distribution or controlled gas composition benefit from stainless steel chambers due to their rigidity and precise manufacturing. For instance, in the production of optical coatings, even minor fluctuations in pressure can affect the quality of the coating layer.

Matching the chamber’s pressure and process capabilities with operational needs ensures consistent and reliable results.

3. Operational and Safety Considerations

Operational factors and safety requirements also influence the decision to use a stainless steel vacuum chamber.

Structural strength: Stainless steel provides sufficient mechanical strength to withstand the forces exerted by a vacuum without collapsing or deforming. This is essential for maintaining safety and operational integrity during prolonged use.

Ease of integration with equipment: Stainless steel chambers can be designed to accommodate sensors, pumps, valves, and feedthroughs for electrical or optical connections. A laboratory performing material analysis may require multiple access points for instrumentation, which can be reliably incorporated into a stainless steel design.

Longevity and maintenance: Stainless steel is durable, reducing the need for frequent replacements. This reliability is critical in environments where downtime can be costly or disruptive, such as research laboratories or industrial production lines.

Safety under vacuum conditions: Properly designed stainless steel chambers minimize the risk of leaks or structural failure under vacuum, ensuring the safety of personnel and equipment.

Operational and safety considerations make stainless steel chambers suitable for long-term and precise applications where reliability is essential.