Jan 02, 2026

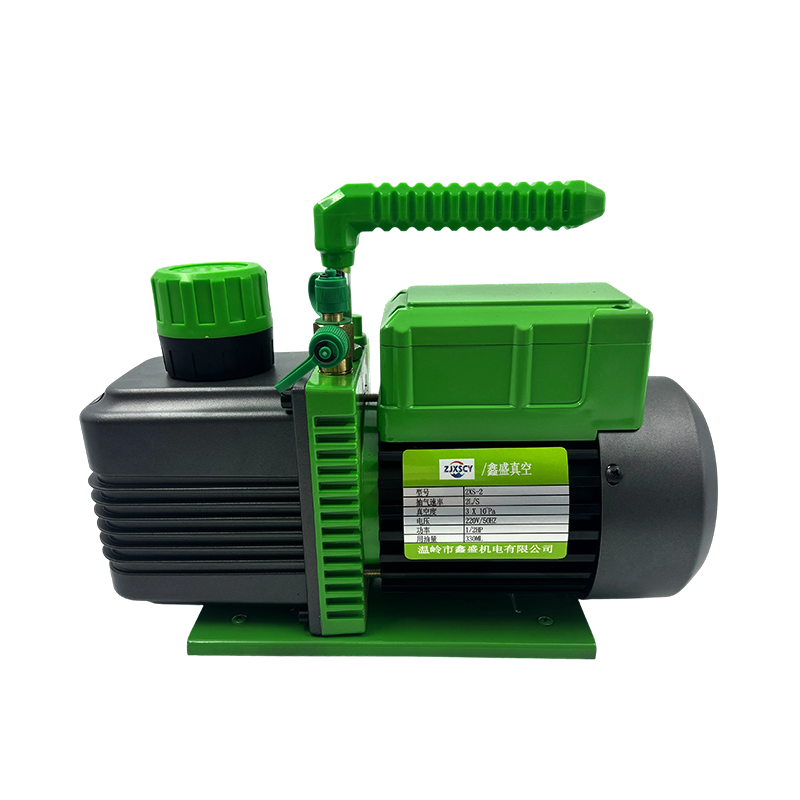

Rotary vane vacuum pumps are widely used in industrial, laboratory, and commercial applications to create a vacuum for processes such as packaging, degassing, and air extraction. These pumps use a rotor with sliding vanes inside a cylindrical housing to draw gas from a system and expel it, generating vacuum pressure.

Early Appearance and Invention

The rotary vane vacuum pump was developed in the early 20th century as engineers sought practical methods to create controlled vacuums for industrial processes. Initial designs used simple mechanical rotors with sliding vanes in a cylinder to move air or gas from an inlet to an outlet. Early pumps were manually operated or connected to electric motors, providing moderate vacuum levels sufficient for emerging manufacturing and laboratory needs.

These generation pumps were valued for their simplicity and compact design, allowing them to replace larger, less efficient vacuum systems such as piston pumps or bellows. However, early pumps faced limitations in materials and sealing technology, which affected their efficiency and durability. Despite these challenges, they laid the foundation for further development in vacuum technology.

Technological Improvements in Design

Over time, rotary vane vacuum pumps underwent significant design improvements to enhance efficiency, reliability, and performance. The rotor and vanes were refined to reduce friction and wear, while the cylindrical housing was redesigned to improve sealing and reduce leakage. Some designs introduced self-adjusting or spring-loaded vanes to maintain consistent contact with the cylinder wall, improving vacuum performance and reducing maintenance needs.

Modern rotary vane pumps often incorporate oil lubrication to improve sealing and cooling. Oil-sealed rotary vane pumps provide higher vacuum levels and smoother operation, making them suitable for laboratory and industrial applications that require consistent vacuum. Additionally, dual-stage designs were developed to achieve deeper vacuum levels, expanding the range of applications for which these pumps could be used.

Material Development and Durability

The development of materials played an important role in advancing rotary vane vacuum pumps. Early pumps often used steel or cast iron components, which were prone to wear and corrosion under continuous operation. Advances in metallurgy and polymer technology allowed manufacturers to use more durable materials for vanes, rotors, and housings, improving lifespan and reliability.

Modern vanes are often made of carbon or composite materials, which offer reduced friction, lower wear rates, and better heat resistance. The use of high-quality seals and corrosion-resistant housings has allowed rotary vane vacuum pumps to operate effectively in challenging environments, including chemical processing and food packaging. Material improvements have also contributed to quieter operation and reduced maintenance requirements.

Expanded Applications and Modern Use

The development of rotary vane vacuum pumps has led to a broad range of applications. In laboratories, they are used for vacuum filtration, degassing, and vacuum drying. In industry, they support packaging machines, air conditioning systems, and printing equipment. Food processing, medical equipment, and automotive manufacturing also rely on these pumps for processes requiring controlled vacuum levels.

Modern pumps are available in oil-sealed and dry-running versions, allowing users to select models based on operational requirements, maintenance preferences, and environmental considerations. Automation and digital monitoring have also been integrated into some pumps, providing real-time feedback on vacuum levels, temperature, and operating status, which improves efficiency and reliability in modern production environments.