Pipe cutters and flaring tools are essential components in plumbing, HVAC systems, and various industrial applications. Designed to enhance the precision and efficiency of pipe installation, these tools are widely used by professionals for cutting and shaping pipes to meet specific installation requirements.

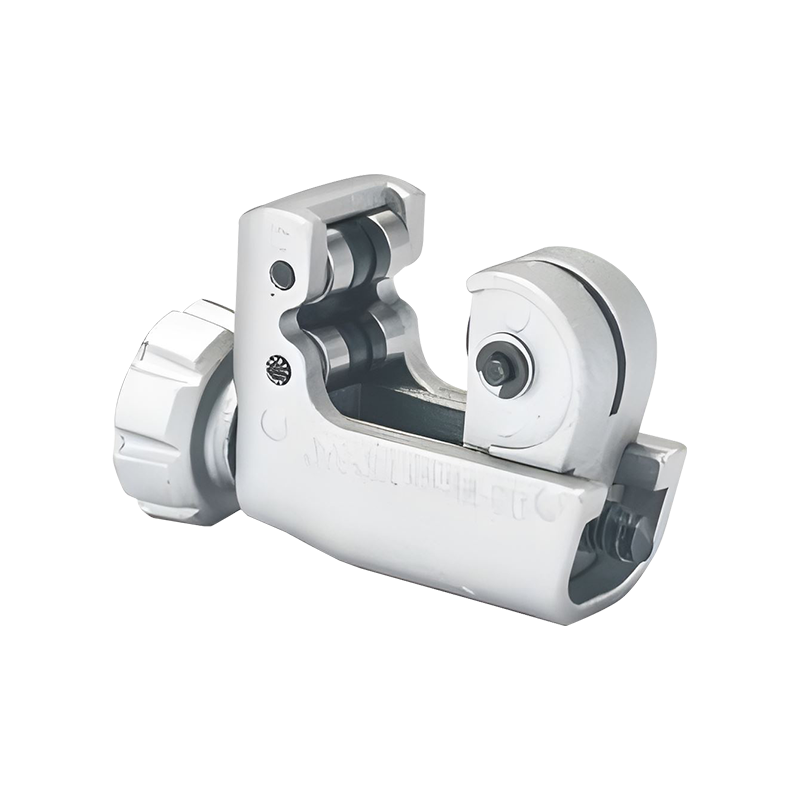

1. Pipe Cutters: High Precision and Clean Cuts

Pipe cutters are specially designed tools used to cut pipes with great accuracy and fewer effort. They are typically equipped with a sharp, rotating blade that slices through the pipe material.

Types of Pipe Cutters: There are several types of pipe cutters available, including rotary cutters, tube cutters, and adjustable cutters. Rotary pipe cutters are ideal for use in tight spaces, while adjustable cutters offer flexibility for different pipe sizes.

Materials and Construction: Pipe cutters are made from durable materials such as hardened steel or stainless steel, ensuring long-lasting performance even under heavy-duty use. Many models feature a replaceable blade, extending the tool’s lifespan.

Versatility: Suitable for cutting pipes made of various materials, such as copper, PVC, steel, and aluminum, these cutters are indispensable in both residential and commercial applications.

Ease of Use: Pipe cutters are designed for comfort, featuring ergonomic handles that reduce hand strain during use. The rotary motion makes cutting effortless, even for thick-walled pipes.

Precision Cutting: A key benefit of pipe cutters is their ability to deliver precise, smooth cuts, ensuring that the pipe ends are even and ready for fittings or connections without the need for further sanding or filing.

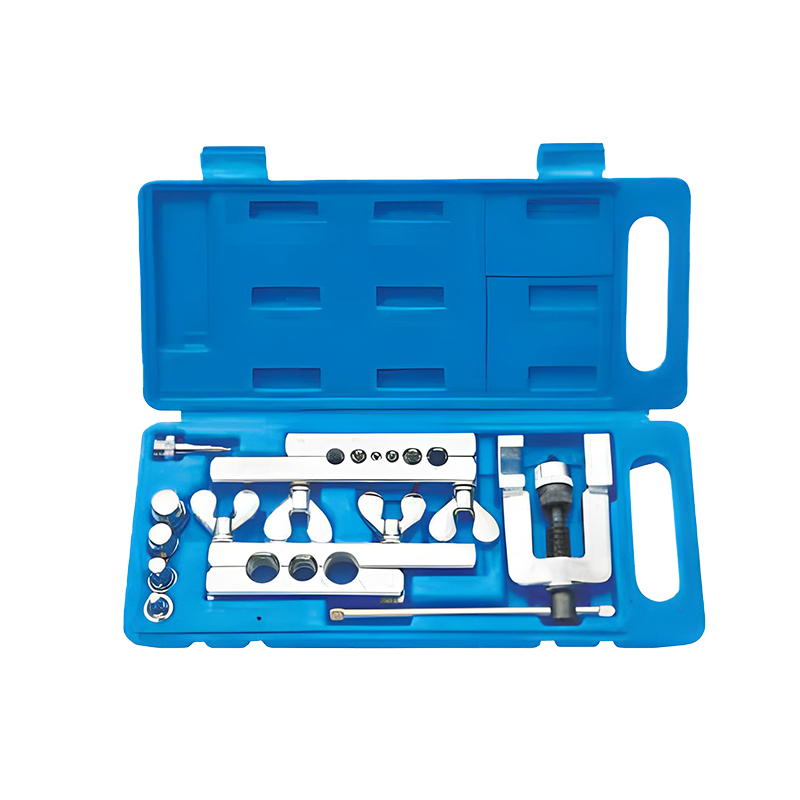

2. Flaring Tools: Secure and Leak-Free Joints

Flaring tools are used to create a flared end on pipes, which is essential for making strong, leak-free connections. This process is commonly used for copper, aluminum, and soft steel pipes, typically in refrigeration, HVAC, and plumbing systems.

Flaring Process: The tool works by expanding the end of the pipe outward, creating a bell-shaped flare. This flare allows the pipe to be connected to other components using a flare nut, creating a tight seal.

Types of Flaring Tools: There are manual, hydraulic, and pneumatic flaring tools. Manual flaring tools are commonly used for smaller applications, while hydraulic and pneumatic models are suited for larger-scale operations or professional-grade projects.

Precision and Consistency: Flaring tools are engineered to create uniform flares, ensuring that the flare is consistent in size and shape. This consistency is crucial for achieving leak-proof connections.

Materials Compatibility: These tools are compatible with various pipe materials, including copper, aluminum, and brass. They are designed to accommodate a wide range of pipe diameters and wall thicknesses.

Adjustable Dies and Settings: Many modern flaring tools come with adjustable dies and settings that allow for customization based on the specific needs of the pipe material and size. This flexibility makes them ideal for diverse applications.

3. Applications in Various Industries

Plumbing: In plumbing, these tools are essential for cutting and shaping pipes for water supply, drainage, and sewage systems.

HVAC Systems: Flaring tools are particularly important for HVAC systems, as they ensure secure and leak-free connections for refrigerant lines.

Refrigeration and Automotive: Both pipe cutters and flaring tools are used in refrigeration systems, automotive air conditioning lines, and other areas that require precise, reliable pipe fittings.