HVAC (Heating, Ventilation, and Air Conditioning) systems are critical to ensuring comfort and air quality in residential, commercial, and industrial buildings. The tools used to install, maintain, and repair these systems need to be precise, durable, and reliable. HVAC tool sets provide technicians with a comprehensive selection of high-quality instruments necessary for performing tasks efficiently and safely.

1. Comprehensive Tool Selection

HVAC tool sets typically come with a wide variety of tools tailored to different tasks, including installation, maintenance, and troubleshooting. These tool sets may include:

Pliers and Cutters: For gripping, bending, and cutting wires and cables. Needle nose pliers, diagonal cutters, and combination pliers allow for precise manipulation of components.

Manifold Gauges: Used to measure the pressure of refrigerants in HVAC systems, providing essential data for system diagnostics and charging.

Leak Detectors: Devices that help identify refrigerant leaks in air conditioning and refrigeration systems, ensuring system efficiency and environmental safety.

Tube Benders and Flaring Tools: These tools help shape metal tubing and flare pipe ends for secure connections in HVAC systems, particularly in refrigerant lines.

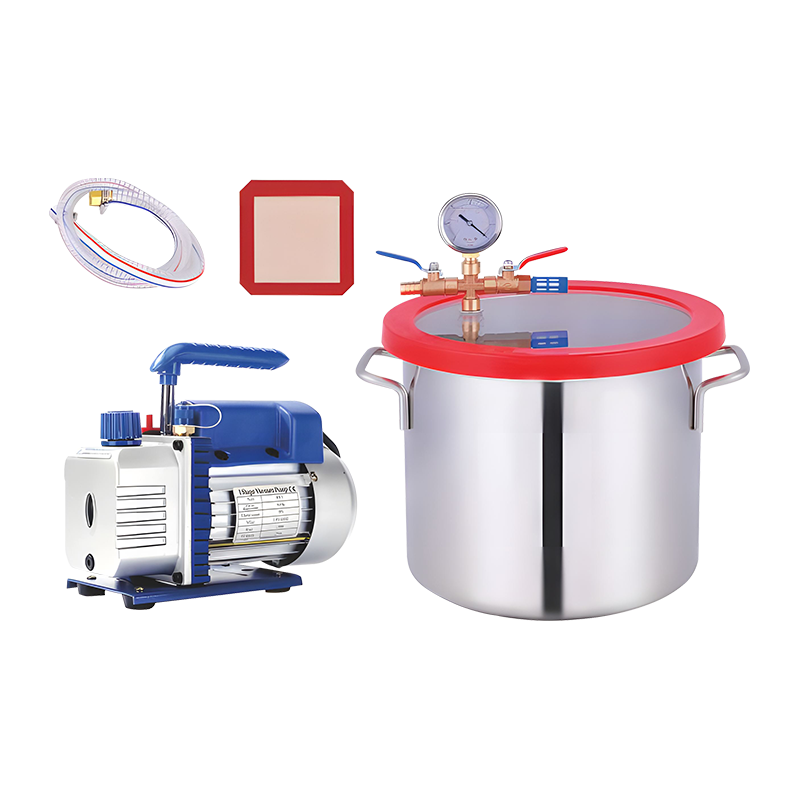

Vacuum Pump: A vacuum pump is an essential tool for evacuating air and moisture from HVAC systems, particularly during installation or servicing. Removing air and moisture helps prevent contamination and ensures the proper operation of refrigeration systems.

Each of these tools plays a specific role in the service, maintenance, and installation of HVAC systems, making a comprehensive tool set an essential asset for any HVAC technician.

2. Durability and Quality Construction

HVAC tools must withstand heavy use and harsh conditions. High-quality materials such as carbon steel, stainless steel, and industrial-grade plastics are commonly used to ensure longevity and performance under demanding circumstances. Durable coatings, such as anti-corrosion finishes, are applied to tools to protect them from rust and wear, especially in environments where moisture and chemicals may be present.

Professional-grade HVAC tool sets are designed to meet the rigorous demands of the trade. Many of these tools are tested for high-performance standards to ensure they can handle the extreme pressures, temperatures, and physical demands often encountered in HVAC systems.

3. Convenience and Portability

HVAC tool sets are designed to offer maximum convenience and portability for technicians who are often required to work in various locations. Tool sets are typically organized in durable carrying cases or toolboxes that make transporting and accessing tools easier.

Some sets also come with roll-up tool bags or soft cases, allowing technicians to carry their essential tools directly to the job site. These bags can be easily stored in service vehicles and accessed quickly, which is crucial for minimizing downtime during repairs or installations.

4. Efficiency and Precision in Service

Using the correct tools for specific tasks ensures greater accuracy, efficiency, and safety when servicing HVAC systems. HVAC tool sets include specialized tools that simplify tasks such as:

Refrigerant Recovery and Charging: With the right manifold gauges and refrigerant hoses, technicians can quickly recover old refrigerant, safely charge systems, and ensure good pressure levels.

Ductwork Installation: Tools like sheet metal snips, crimpers, and duct expanders make the installation of ductwork more precise and efficient, allowing for seamless connections and better airflow.

By providing the necessary tools for each task, HVAC tool sets allow technicians to work with greater efficiency and precision, to quicker job completions and higher customer satisfaction.